Product Details

MSRP $43.57

MPN 044178

UPC 090255441789

Description

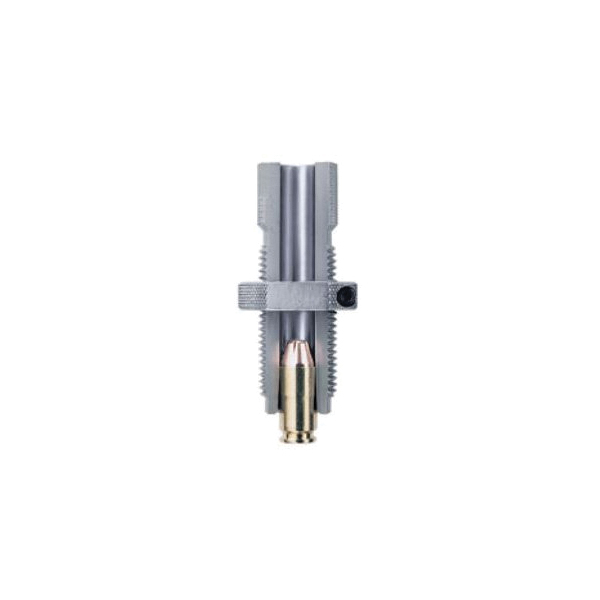

The Hornady .40 S&W/10mm pistol taper crimp bullet seating die is a precision-engineered component designed for reloading enthusiasts seeking optimal performance and reliability. This die is specifically tailored for .40 S&W and 10mm Auto cartridges, ensuring consistent bullet seating and crimping for enhanced accuracy and functionality. Constructed from high-grade steel, the die offers exceptional durability and resistance to wear, making it suitable for high-volume reloading operations. The taper crimp feature is meticulously designed to provide a secure hold on the bullet without deforming the case, thereby maintaining the integrity of the ammunition and ensuring smooth chambering and extraction. The Hornady die incorporates a micrometer adjustment system, allowing for precise control over bullet seating depth. This feature facilitates quick and accurate adjustments, enabling users to achieve consistent results with minimal effort. The die is compatible with standard reloading presses, offering seamless integration into existing reloading setups. Overall, the Hornady .40 S&W/10mm pistol taper crimp bullet seating die is an essential tool for reloaders who demand precision and reliability in their ammunition crafting process. The seater adjustment screw facilitates precise calibration of bullet seating depths, ensuring optimal alignment and consistency in ammunition assembly The compression lock utilizes an O-ring to provide the required tension, facilitating precise adjustments and ensuring the die set remains securely in position Taper crimp adjust screw - precisely modulates crimp intensity on the cartridge, maintaining consistent bullet seating depth and securing the lock ring in a fixed position The ergonomic architecture of this die facilitates simultaneous seating and taper crimping, obviating the necessity for an additional taper crimp die, thereby streamlining the process The Hornady Sure-Loc lock rings encircle the die, exerting uniform pressure to secure the ring The locking screw fastens the ring without thread contact, preventing potential damage from pliers The in-line bullet seating system ensures precise alignment of the bullet, case neck and seating stem within the sleeve prior to the bullet entering the case neck This system comprises a floating bullet alignment sleeve, a floating steel seating stem and an integrated crimper, all designed to achieve benchrest precision As bullets enter the die, they are aligned within the sleeve to ensure optimal seating and improved accuracy