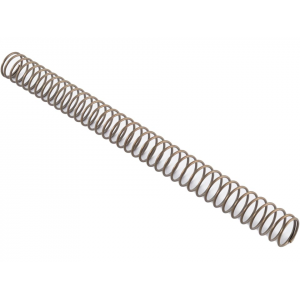

Wilson Combat Low Mass Bolt Carrier Assembly .308 Cal/7.62x51mm/.243 Caliber

Shop Wilson Combat Products

Product Details

MSRP $319.95

MPN TR-BCA-LM-NB-308

UPC 810025505363

Description

The Wilson Combat bolt carrier assembly for .308 Winchester is engineered with precision to deliver unmatched performance and reliability in critical moments. Crafted from aerospace-grade 9310 tool steel, this lightweight, low mass bolt carrier assembly offers exceptional toughness and durability. Each unit undergoes rigorous magnetic particle Inspection (MPI) to ensure peak performance standards are met. The carrier itself is made from 8620 hardened steel, featuring forward assist cuts for enhanced functionality. The gas key is securely staked with grade 8 fasteners, eliminating concerns about gas leakage or failure under high pressure. The assembly is finished with a corrosion-resistant nickel boron coating, which not only enhances durability but also provides increased lubricity for smoother cycling of your rifle. Designed for optimal recoil control and rapid follow-up shots, this low mass bolt carrier group is an excellent choice for sporting or competition rifles. Its lightweight design facilitates quicker lock-up times, especially when paired with an adjustable gas block to fine-tune cycling pressure and timing. Experience the perfect blend of precision engineering and advanced materials with the Wilson Combat bolt carrier assembly, ensuring your rifle performs flawlessly when it matters most.The nickel boron coating, with its polished finish, facilitates easy cleaning and offers protection against corrosionThe carrier is manufactured from 8620 hardened steel and includes forward assist cutsThe gas key is secured with grade 8 fasteners to prevent gas leakage or failure under pressureMachined ejector and extractorOptimized for .308 Cal/7.62x51, .243 Cal, 6.5 Creedmoor, .260 Cal, .338 Cal and other calibers based on the .308 WinMagnetic particle inspection (MPI) for optimal performance to ensure optimal performance, it is essential to conduct magnetic particle inspection (MPI) with precision and adherence to established protocolsThis non-destructive testing method is employed to detect surface and near surface discontinuities in ferromagnetic materialsBy applying a magnetic field to the test object and introducing magnetic particles, any disruptions in the magnetic field caused by defects become visible, allowing for accurate identification and assessmentProper execution of MPI requires a thorough understanding of the equipment, materials and techniques involved, as well as strict compliance with safety standards and guidelines